Tips, tricks and what you need to know.

We get asked a lot about pixel tape (sometimes known as ‘smart tape’ or ‘intelligent tape’).

The first thing that most people want to know is exactly what pixel tape does and how it differs from standard RGB LED tape. But there’s a lot more to pixels than the answer to this query alone. Also, at ENTTEC, we make pixel dots as well, so people naturally want to know how these fit into the mix too.

With our growing range of pixel products becoming increasingly popular throughout the entertainment and architectural lighting industries, we thought it was a good time to put some of your most common questions to our Research & Development team and come up with some expert answers to help set you on your merry way (especially if you’re just starting out on your lighting control adventures, in which case, welcome onboard!).

Contents

Introduction

Designing Your System

Questions & Answers

What’s the difference between RGB and RGBW tape?

How many DMX channels are there per pixel tape ?

What type of surface will be suitable for installing pixel tape?

How do I wire pixel tape to a Pixie Driver?

How do I wire pixel tape with a Plink Injector?

Why do LEDs at the end of white tape turn warm white or pink?

Will non-ENTTEC tape work with an ENTTEC Pixelator/Pixie Driver?

Why does my pixel tape flicker at the end?

Introduction to Pixel Tape

What is Pixel Tape?

Pixel tape is flexible circuit board which is populated by multicoloured, addressable surface mounted (SMD) light-emitting diodes (LEDs). The flexible circuit board usually has an adhesive backing, which aids with quick and easy installation.

Unlike standard RGB tape, each LED has its own chip which enables it to be controlled to respond (e.g: change colour, switch off etc) individually. Pixel tape can still do everything that standard RGB tape can do … only more.

Designing Your System

While we’re mostly going to focus on pixel tape here, we wouldn’t be ENTTEC if we didn’t at least mention pixel dots. When it comes to dots versus tape, both products are easy to install and share a certain degree of functionality, so which should you choose?

The answer is going to depend upon your intended application and the space you have available in which to create it. Consider the following points:

Pros of using tape

• Steady and consistent light

• Lightweight

• Takes up less physical space than dots

• Easy to make unobtrusive beneath a diffuser

• Good for ephemeral installations on a small budget

Pros of using dots

• Higher IP rating than tape

• More visual appeal as a conspicuous feature

• Greater light output

• Robust construction: hard-wearing and longer-lasting

• No extrusions required or heat management issues

• Can be installed into virtually any conceivable shape

• Wide variety of designs to choose from

Whichever you decide to go with, there are a few basic tenets that you should give serious consideration to prior to getting your project started.

Firstly, remember that each project is unique. The pixel product you’ll want to purchase will vary depending on a number of factors including (but not limited to) aesthetics, environment and the availability of space. So before you hand over your hard-earned cash, have a good think about the following:

• What type of aesthetics does the project require?

• Where will the LED tape be placed?

• What type of surface will the LED tape be placed on or within?

RETURN TO CONTENTSWhy should I use ENTTEC tape as opposed to other brands?

ENTTEC tapes are designed to surpass industry benchmarks, not merely conform to them. We make it our mission to use better substrates and thicker copper than other tapes on the market. Manufactured to the highest standards, our tapes are then quality checked and tested by our team of engineers in order to ensure optimal compatibility with our popular range of pixel controllers.

Thicker copper tracks offer more durability, better heat dissipation and improved current flow, all of which are vital factors towards achieving the best possible product. Heat dissipation in particular is a critical safety issue when it comes to high density tapes, so we pay serious attention to the amount of copper we use on our tapes.

Inferior PCB tapes commonly have a copper thickness of around one ounce per square foot, whereas we require our tapes use three times that amount (the exception being 8PL60-12 which uses 2oz/sqf).

TAPE TYPE |

OUNCES OF COPPER (PER SQUARE FOOT) |

| 8PL30 | 3 |

| 8PL60 | 3 |

| 8PX60 | 3 |

| 8PL144 | 3 |

| 8PL60-12 | 2 |

So with ENTTEC, you know you’re in safe hands.

And lastly, regardless of which product you end up using, never forget …

All pixel tape should be installed by a qualified electrician!

RETURN TO CONTENTSQuestions & Answers

Do I need 5 V or 12 V tape?

This depends on the end user application.

12V means 3 leds = one pixel, 5V each led is a pixel. Power usage is the same.

The colour change due to voltage drop on 5 V pixel tape is more apparent than on a 12V. Therefore, the maximum possible run of a 12V is higher than a 5V tape. However, the power consumption of a 12V tape is higher than a 5V reel. Therefore, it’s best to calculate and understand the power availability of your system before making a purchase.

RETURN TO CONTENTSWhat about RGB versus RGBW tape? Which do I choose?

This again depends on the end user application.

RGB Pixel Tape uses a 3-in-1 colour (red, green and blue) LED chip. By having the three colours, red, green and blue, at full brightness, the end user can obtain a nearly white colour. RGB Tape also uses 3 channels per led, which means lesser number of DMX universe, when it comes to mapping them.

RGBW Pixel tape has a 4-in-1 colour (red, green, blue and white) LED chip. Although RGB can produce a colour close to white, the dedicated white LED of the RGBW Pixel Tape provides a much purer white tone. RGBW tape uses 4 channels per led, which means a larger number of DMX universe will be required during mapping the Tape.

RETURN TO CONTENTSHow many DMX channels are there per pixel tape ?

The reason it’s called pixel tape is that it can treat each dot on the tape as a separate combination of RGB.

• 1 Pixel = 3 DMX Channels (RGB)

• 1 Pixel = 4 DMX Channels (RGBW)

With different densities of LED on the tape, and different lengths, you can multiply it all together and get a variety of results.

For instance:

• (8PL30) 30 RGB LEDs/m tape x 5 metre reel = 150 pixels (150 pixels x 3) = 450 channels

• (8PL60) 60 RGB LEDs/m tape x 5 metre reel = 300 pixels (300 pixels x 3) = 900 channels

• (8PL144) 144 RGB LEDs/m tape x 2 metre reel = 288 pixels (288 pixels x 3) = 864 channels

• (8PX30) 30 RGBW LEDs/m tape x 5 metre reel = 150 pixels (150 pixels x 4) = 600 channels

• (8PX60) 60 RGBW LEDs/m tape x 4 metre reel = 240 pixels (240 pixels x 4) = 960 channels

Handy to remember:

• 170 RGB Pixels = 510 DMX Channels = 1 DMX Universe

• 128 RGBW Pixels = 512 DMX Channels = 1 DMX Universe

Our products can drive up to 2U per port:

Product |

RGB Pixels |

RGBW Pixels |

| Pixie Driver | 170 | 128 |

| Pixelator | 340 | 256 |

| Pixelator Mini | 340 | 256 |

| Pixelator Mini PX1-8D | 340 | 256 |

| PSAT | 340 | 256 |

| Pixel Port | 340 | 256 |

What type of surface will be suitable for installing pixel tape?

The pixel tape should be installed on a clean and dry surface. Please clean the surface with alcohol using a clean cloth prior to installation.

The surface should be thermally conductive and permit sufficient heat dissipation from the tape. Check out ENTTEC’s extrusions to get an idea of the best surfaces for optimum performance (note: these products are not presently available for purchase in Europe, but European visitors are welcome to view them for educational purposes on our Asia-Pacific website here).

Surface should not be textured or a low surface energy material.

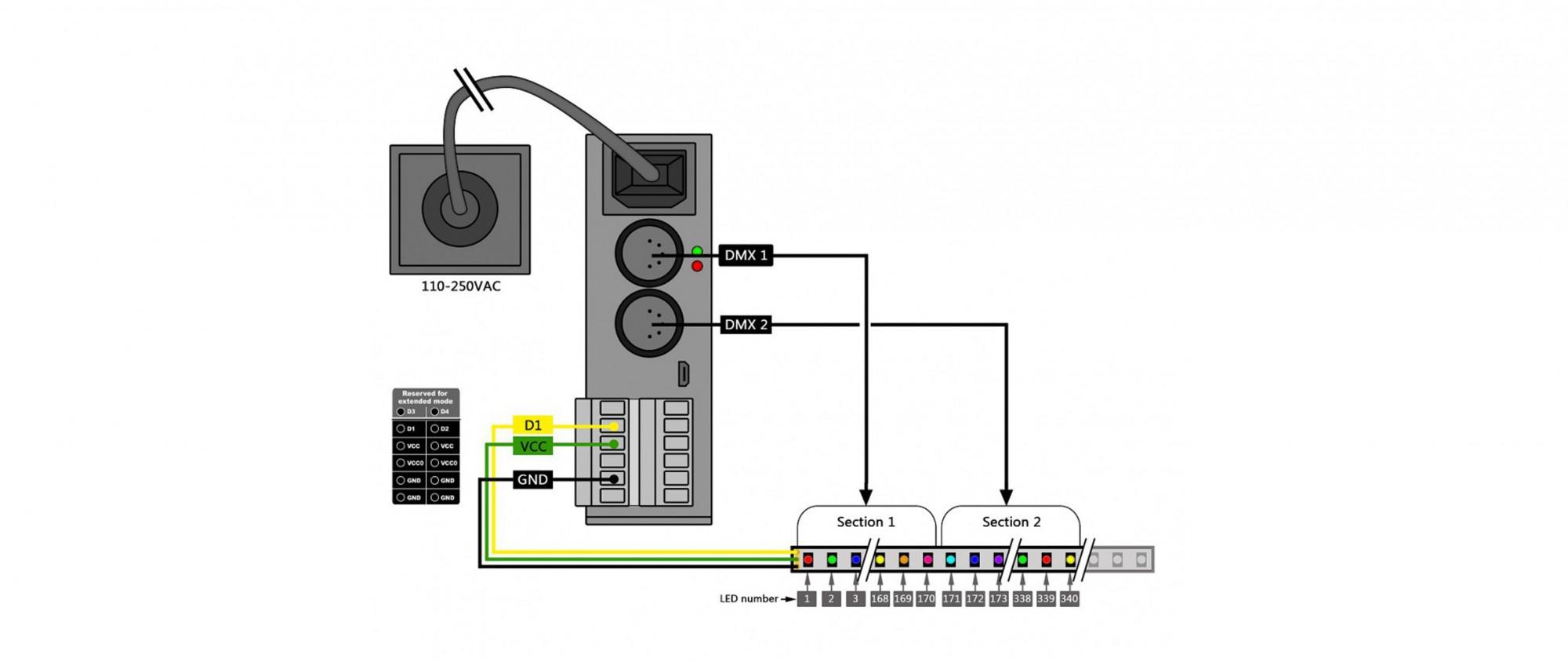

RETURN TO CONTENTSHow do I wire pixel tape to a Pixie Driver?

Like this:

For more information please refer to the Pixie Driver User Manual.

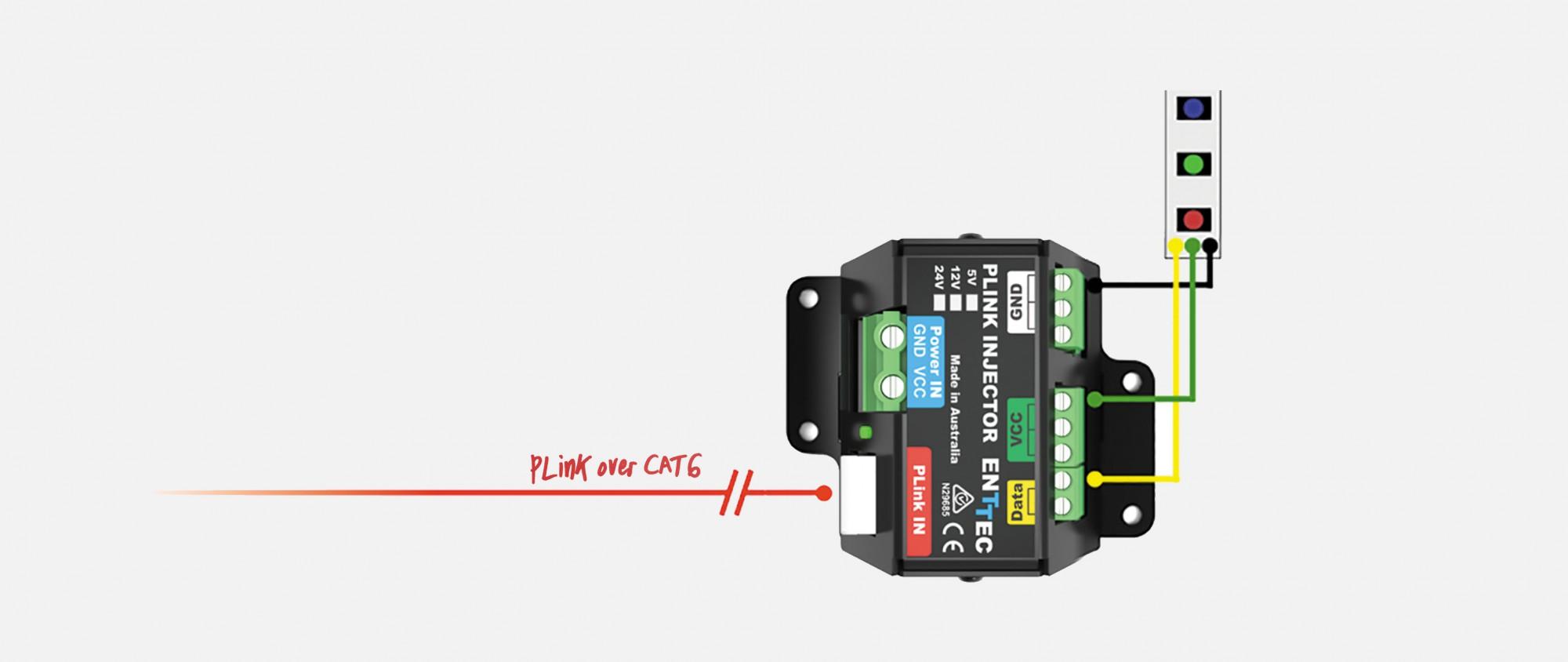

RETURN TO CONTENTSHow do I wire pixel tape with a Plink Injector?

Like this:

For more information please refer to the Plink application diagram available HERE.

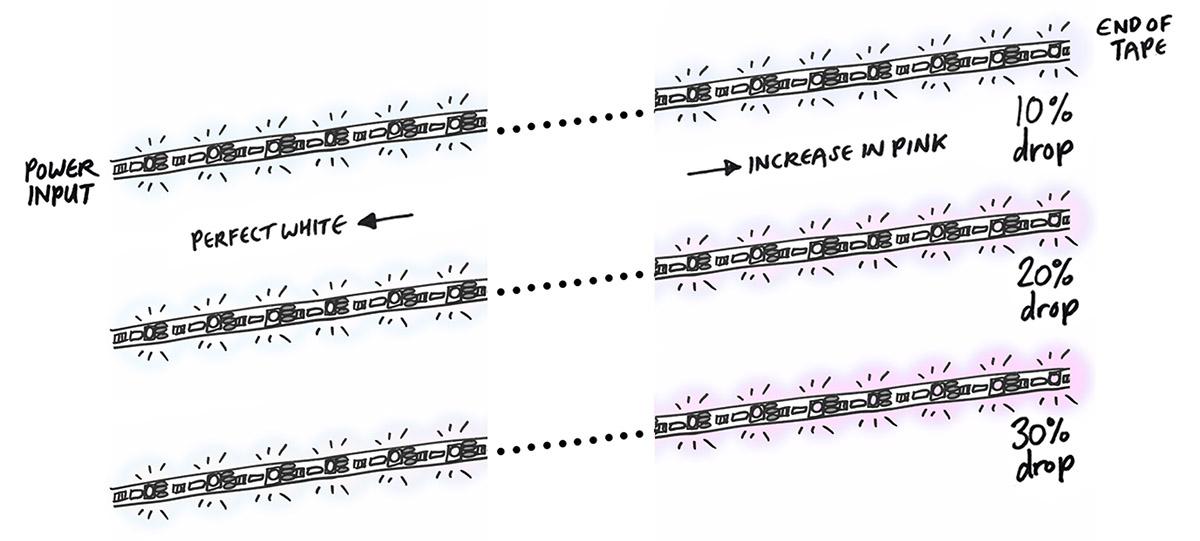

RETURN TO CONTENTSWhy are LEDs at the end of the tape warm white/pink when driven white?

This occurs because of voltage drop along the LED tape when attempting to power a longer length of the tape. As a result, of the voltage drop, pixels along the tape would gradually vary in colour when driven white. It is best to determine the maximum possible length of run before voltage drop will begin to affect (x metres) and to inject power after every x metres.

The greater the drop in voltage along a series of white LEDs, the more pink in hue those furthest away from the power source will appear. The entire length will also marginally decrease in brightness as the voltage lowers. The majority of tapes and dots display these phenomena in a very subtle fashion while some others may be slightly more pronounced. Likewise, the degree to which the human eye perceives it will naturally differ from person to person, but most people will find the colour change virtually indiscernible.

(PLEASE NOTE: The above drawing is not intended to be an accurate scientific diagram. It’s a simple visual representation to give you a rough idea of the sort of effect you might sometimes observe when different percentages of voltage drop occur.)

RETURN TO CONTENTSI sourced some pixel tape from Amazon/Alibaba/Honest Bob’s Super-Cheap Discount Lighting Warehouse™. Will it work with an ENTTEC Pixelator/Pixie Driver?

This will depend on the protocol of the tape sourced and the wiring involved. There are two different types of wiring: 3-wire or 4-wire tape. All ENTTEC pixel controllers only support 3-wire tape.

ENTTEC’s Pixie Driver supports the following protocols:

• 9PDOT-8bit

• WS2811, WS2812, WS2812B

• APA-104 LEDs

ENTTEC Pixelator and Pixelator Mini support the following protocols:

• 9PDOT-8bit

• 9PDOT-16bit

• WS2811, WS2812, WS2812B, WS2813

• SK6812

• TM1804

• TM1812

• APA-104 LEDs

Please note: 9PDOT protocols are only supported by revB (units sold from 2017 onwards). There may be other LED protocols similar to the ones supported by ENTTEC. We cannot claim to support all of them, but if you do happen to find one that works and is not listed, please let us know so we can update our documentation.

RETURN TO CONTENTS

Why does my pixel tape flicker at the end?

This occurs because of voltage drop along the LED tape when attempting to power too long of a strip. As a result of the voltage drop, pixels at the end of the tape would flicker. It is best to determine the maximum possible length of run before voltage drop will begin to affect (x metres) and to inject power after every x metres.

RETURN TO CONTENTS